Recondition of Cylinder Head / MAN L32/40

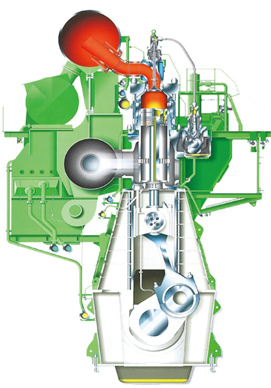

Cylinder head

- Used cylinder head was pre-inspected and reported to the customer

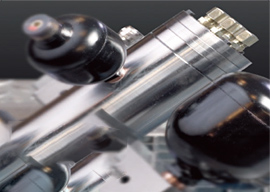

- All components of cylinder head were dismantled ;

All valve cone and spring with rotor cap was dismantled.

All insert of fuel injection valve was dismantled / All stud and plug were dismantled. - Inner surface of cylinder head was found that many the carbon deposit. It was cleaned by special chemical and brush.

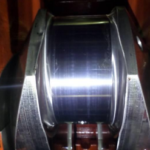

- Valve cone seat width of intake and exhaust valves were inspected and measured.

- All valve seat of cylinder head was visually inspected

- Inner diameter of all valve guide was measure

- All bush of rocker arm bridge was replaced by new one

- After replaced all spare parts on cylinder head, it was tested leakage condition by 7.0 bar